JOJUN EXCELLENT MANUFACTURER OF THERMAL FUNCTIONAL MATERIAL

Focus on heat dissipation, heat insulation, thermal insulation material production for 15 years

- tiger.lei@jojun.net

- 24-hour VIP service hotline:+86 13656269868

Typical Properties of JOJUN-6200 Series Thermal Pad

Typical Properties Of Jojun-6200 Series Thermal Pad

|

Typical Properties Of JOJUN6200 |

|||

|

Property |

Unit |

Product Series |

Test Method |

|

JOJUN6200 |

|||

|

Color |

Customized |

Visual |

|

|

Thickness |

mm |

0.5-5 |

ASTM D374 |

|

Specific Gravity |

g/cc |

2.8 |

ASTM D792 |

|

Hardness |

Shore oo |

20-70 |

ASTM D2240 |

|

Application Temperature |

℃ |

-50 - +200 |

|

|

Flammability Class |

V0 |

UL94 |

|

|

Thermal Conductivity |

W/m-K |

2 |

ASTM D5470 |

|

Breakdown Voltage |

KV/mm |

>6 |

ASTM D149 |

|

Volume Resistivity |

ohm-cm |

10 ^14 |

ASTM D257 |

|

Dielectric Constant |

1MHz |

7 |

ASTM D150 |

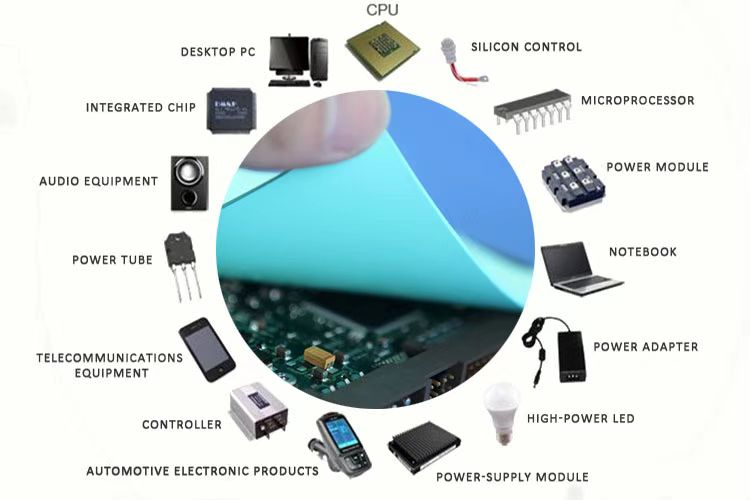

Introduction

The heat conduction pad has good heat conduction capacity and high level of pressure resistance,

It is a substitute for thermal conductive silicone grease, and the material itself has certain

Flexibility, good fit between power device and heat sink aluminum sheet or machine

Between the shells to achieve the best heat conduction and heat dissipation

The former electronic industry's requirement for thermal conductive materials is to replace thermal conductive silicone grease

The best product of the binary heat dissipation system with hot paste and mica chip. In the industry

It can also be called thermal conductive silica gel sheet, thermal conductive silica gel pad, thermal conductive silica gel

Rubber pad, insulating heat conduction sheet, soft heat dissipation pad, etc.

★ Production Process

Mix Stir

Extrusion

Thermal Pad Production Line

Crop

Package

Outgoing Goods

★R&D Center

Voltage Breakdown Tester

Thermal Conductivity Tester

Kneader

Laboratory

★ Service

Our team

We are a dedicated team, we meet and win trust

From customers with qualified products

Quality

The enterprise strictly abides by

Material and equipment quality control system

Procurement, production and quality control.

Fast delivery

With first-class products, excellent service and fast service

Delivery and the most favorable price, we have won a very high

Praise foreign customers

★ FAQ

Q: How to control product quality?

We have a systematic quality control and inspection process. From product quality control plan, to the conversion of inspection standards, to the implementation of quality inspection plan, the quality control of process nodes consists of incoming materials, product process and final inspection

Q: When will the goods be shipped?

This depends on the order quantity and requirements. It takes 3-7 days for conventional products and 25-40 days for customized products. Our daily output is 1 million pieces, so we can deliver in a short time.

★ Certificates

Features of Thermal Products

-

Features of Thermal Pad

1. Good thermal conductivity: 1-15 W/m-K.

2. Low hardness: The hardness ranges from Shoer00 10~80.

3. Electrically insulating.

4. Easy to assembly. -

Features of Thermal Paste

1. Two-part dispensable gap filler, liquid adhesive.

2. Thermal conductivity: 1.2 ~ 4.0 W/m.K.

3. High voltage insulation, high compression, good temperature resistance.

4. Compression application, can achieve automated operations. -

Features of Thermal Grease

1. Low oil separation (towards 0).

2. Long-lasting type, good reliability.

3. Strong weather resistance (high and low temperature resistance -40~150 ℃).

4. Moisture resistance, ozone resistance, aging resistance.