When the temperature is too high, people usually stop working or use external tools to physically cool down, but some machines and equipment that need to work around the clock are not allowed. The nature of their work means that they have to work all the time, except for short-term maintenance. Therefore, it is necessary to do a good job of internal heat dissipation.

Machines and equipment are generally equipped with heat dissipation devices for heat dissipation, because air is a poor conductor of heat, and most of the machines and equipment are relatively sealed inside, and the heat is not easy to dissipate outside, so the heat is easy to accumulate and make the local temperature rise, which affects the machine. The normal operation of the equipment, so the cooling device will be used.

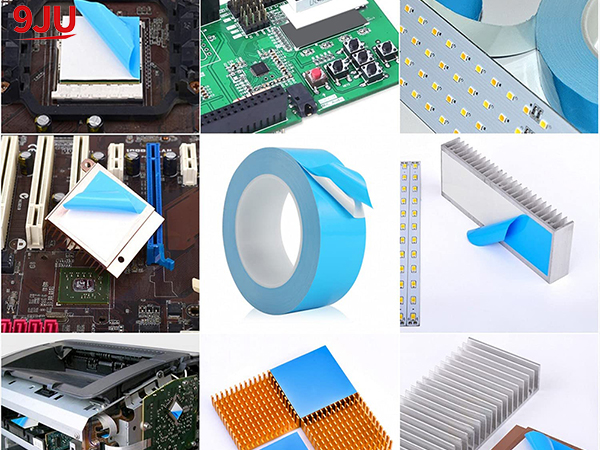

Heat dissipation devices such as heat dissipation fans, heat sinks, and heat pipes are in contact with the heat source in the equipment, and conduct the temperature on the surface of the heat source to the heat dissipation device to reduce the temperature inside the equipment. There is a gap between the heat dissipation device and the heat dissipation device in the equipment, and the heat from The heat-generating device will slow down when it conducts to the heat-dissipating device, so thermally conductive materials will be used.

Thermally conductive insulating sheet is one of many thermally conductive materials. The difference between thermally conductive insulating sheet and thermally conductive silicone sheet is that it has a high breakdown voltage value, which can prevent the gasket from being broken down and affect the use of equipment parts. In addition to high breakdown voltage, it has high toughness and is very thin, and has its application cases in many environments with large voltage fields.

Post time: Jun-27-2023