Thermal Silicone Pads: A Popular Choice for Thermal Management

In the world of electronic devices and components, thermal management is a key consideration. Excessive heat can cause performance degradation, shortened service life, and even permanent damage to sensitive electronic equipment. To solve this problem, thermally conductive silicone pads have become a popular solution to effectively dissipate heat and ensure optimal operation of electronic devices. In this article, we will explore the reasons behind the popularity of thermally conductive silicone pads and their widespread use in various industries.

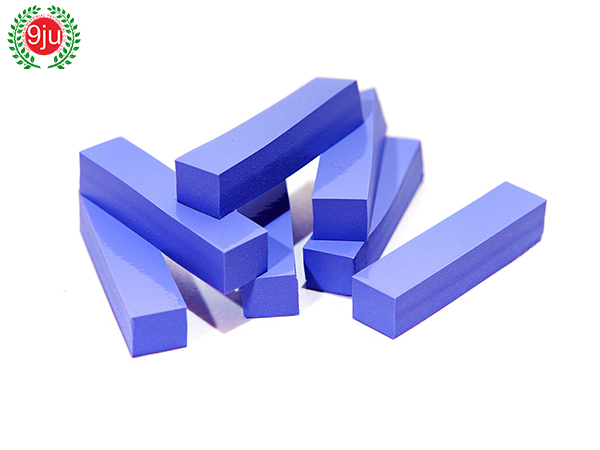

Thermal silicone pads are designed to provide efficient heat transfer between electronic components and heat sinks or other cooling devices. Made from a combination of silicone and thermally conductive fillers, these pads effectively conduct heat away from sensitive components. The flexibility and comfort of the silicone pad enable it to come into close contact with uneven or irregular surfaces, ensuring maximum heat transfer and thermal management.

One of the key reasons for the popularity of thermally conductive silicone pads is their excellent thermal conductivity. These pads are engineered to have high thermal conductivity, effectively moving heat away from hot spots on electronic components. This characteristic is critical to maintaining the optimal operating temperature of electronic devices, preventing overheating, and ensuring long-term, reliable performance.

Additionally, thermal silicone pads offer a neat and easy-to-use alternative to traditional thermal interface materials such as thermal grease or phase change materials. Unlike thermal grease that is messy and difficult to apply, silicone pads are clean and easy to install, making them the first choice for manufacturers and engineers. Additionally, silicone pads eliminate the risk of air pockets or voids that can occur with thermal grease, ensuring consistent and reliable thermal performance.

Another factor in the popularity of thermal silicone pads is their versatility. These pads are available in a variety of thicknesses, hardnesses and thermal conductivities, allowing engineers to select the most appropriate pad for their specific application. Whether it is a small electronic device or a large industrial application, thermally conductive silicone pads can be customized to meet the thermal management requirements of different electronic systems.

In addition, thermally conductive silicone pads have excellent electrical insulation properties, making them ideal for applications requiring electrical isolation. This feature ensures that the pads do not interfere with electrical components while effectively dissipating heat, providing dual benefits for electronic devices requiring thermal management and electrical insulation.

The durability and reliability of thermal silicone pads also contribute to their widespread adoption. These pads are designed to withstand harsh environmental conditions, including temperature changes, humidity and mechanical stress. As a result, they provide long-term thermal management solutions for electronic devices, ensuring consistent performance and reliability throughout the product’s life cycle.

In addition to their technical advantages, thermally conductive silicone pads are also a cost-effective thermal management solution. They are easy to install and reliable over the long term, resulting in cost savings for manufacturers and end users. By reducing the risk of heat-related failure and extending the life of electronic components, silicone pads help reduce overall costs and improve product quality.

The popularity of thermally conductive silicone pads spans a variety of industries, including consumer electronics, automotive, telecommunications, and industrial equipment. From smartphones and laptops to LED lighting and power electronics, these pads have become an integral part of thermal management strategies in modern electronic devices.

In summary, the popularity of thermally conductive silicone pads can be attributed to their excellent thermal conductivity, ease of use, versatility, electrical insulation properties, durability, and cost-effectiveness. As electronic devices continue to increase in complexity and performance, the need for efficient thermal management solutions will only increase, further solidifying thermally conductive silicone pads as a popular choice for solving thermal challenges in the electronics industry.

Post time: Jul-19-2024