Thermal pads are important components in electronic devices and systems, playing a vital role in managing heat dissipation and ensuring optimal performance. These pads are designed to provide a reliable and efficient thermal interface between heating components and heat sinks or other cooling solutions. In this article, we will explore the characteristics and applications of thermal pads, emphasizing their importance in various industries and electronic devices.

Characteristics of thermal pads

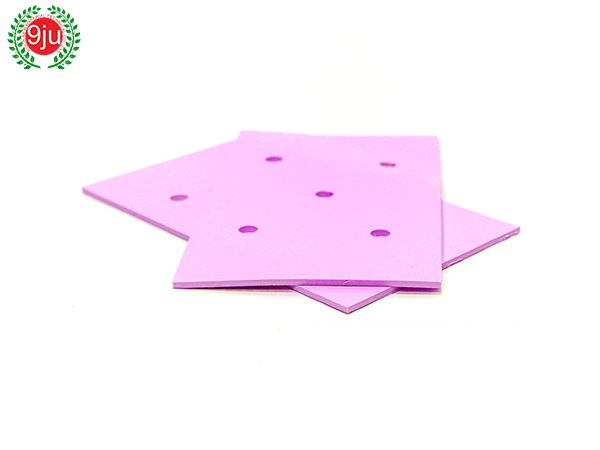

Thermal pads are made from a variety of materials, including silicon-based compounds, graphite, and ceramic-filled polymers. These materials were chosen for their high thermal conductivity, flexibility and durability. One of the main features of thermal pads is their ability to adapt to uneven surfaces, ensuring maximum contact and heat transfer between components and cooling solutions.

In addition, thermal pads are available in different thicknesses and thermal conductivity coefficients to meet specific application requirements. This versatility allows thermal management solutions to be customized and optimized in a variety of electronic devices and systems. Additionally, some thermal pads are designed with adhesive backing that allows for easy and secure attachment to heating components and heat sinks.

Thermal Pad Applications

Thermal pads are widely used in various industries and electronic equipment, including computers, smartphones, automotive electronics, LED lighting and power electronics. In computers and smartphones, thermal pads are used to facilitate heat dissipation from central processing units (CPUs), graphics processing units (GPUs), and other high-power components to heat sinks or cooling modules.

In the field of automotive electronics, thermal pads are used in electric vehicle battery management systems, power modules and motor drives to ensure efficient heat transfer and thermal stability. The use of thermal pads in LED lighting systems is critical to maintaining the optimal operating temperature of the LEDs, thereby extending their lifespan and ensuring consistent performance.

Additionally, thermal pads are an integral part of power electronics applications such as inverter modules, power converters, and voltage regulators, where they help manage the heat generated during high-power operation. The versatility and reliability of thermal pads make them indispensable in a variety of electronic devices and systems across different industries.

Advantages of thermal pads

Thermal pads offer several advantages over traditional thermal interface materials such as thermal grease and phase change materials. One of the main advantages is its ease of application, as the thermal pad can simply be placed between the component and the heat sink without complex application procedures.

Additionally, thermal pads eliminate the risk of air gaps, which can impede heat transfer and compromise the thermal performance of the system. The consistency of the thermal pad ensures even contact and thermal conductivity, thereby improving heat dissipation and overall system reliability.

Additionally, thermal pads are non-curing and non-conductive, making them safe and easy to handle during installation and maintenance. Their non-abrasive nature also prevents damage to components and heat sink surfaces, extending the life of your electronic equipment.

In summary, thermal pads are important components in electronic devices and systems, providing reliable and efficient thermal management solutions. With their versatile functionality and wide range of applications, thermal pads play a key role in ensuring optimal performance and reliability of electronic devices across industries. As technology continues to advance, the need for high-performance thermal pads will only continue to grow, driving innovation and advancement in thermal management solutions.

Post time: Aug-05-2024