Thermal silicone pads are important components in electronic devices and systems, performing the critical function of dissipating heat to ensure optimal performance and longevity. These pads are designed to provide efficient thermal conductivity while addressing environmental concerns. In this article, we will explore the structural and environmental aspects of thermally conductive silicone pads.

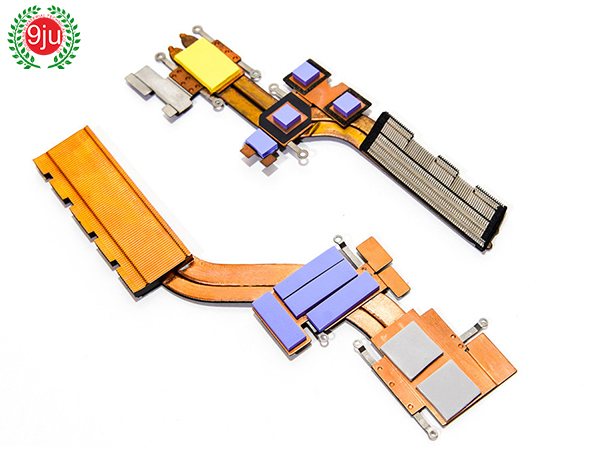

Thermal silicone pads consist of a silicone matrix filled with thermally conductive particles such as ceramic fillers or metal oxides. The silicone matrix provides the pad’s flexibility and comfort, allowing it to conform to uneven surfaces and fill gaps between components. This ensures efficient heat transfer and thermal management within electronic devices.

Thermal conductive particles dispersed in the silicone matrix play a vital role in enhancing the thermal conductivity of the gasket. These particles form a conductive network that facilitates the transfer of heat from the heating component to the surrounding environment. The size, shape and distribution of these particles in the silicone matrix are carefully designed to optimize thermal performance.

In addition to thermally conductive fillers, some silicone pads may contain insulating fillers to provide electrical isolation between components. This dual functionality makes thermally conductive silicone pads suitable for a variety of electronic applications ranging from consumer electronics to automotive and industrial systems.

Environmental considerations are becoming increasingly important in the design and manufacture of electronic components, including thermally conductive silicone pads. Manufacturers are working hard to develop products that not only offer high performance but also minimize environmental impact throughout their life cycle.

One aspect of the environmental protection of thermally conductive silicone pads is the use of materials that do not contain harmful substances. Silicone is the main material used in these mats and is known for its inert and non-toxic nature. Additionally, manufacturers are increasingly choosing thermal fillers that are free of heavy metals and other harmful compounds to ensure their pads are environmentally friendly.

The production process for thermally conductive silicone pads is also being optimized to reduce energy consumption and minimize waste generation. Advanced manufacturing techniques such as compression molding or extrusion are used to achieve high material efficiency and minimize the environmental footprint of the production process.

In addition, the longevity and reliability of thermally conductive silicone pads extend the life of electronic devices and help protect the environment. By efficiently dissipating heat and maintaining optimal operating temperatures, these pads help prevent premature failure of electronic components, reducing the need for frequent replacement and minimizing electronic waste.

For end-of-life considerations, thermal silicone pads are recyclable. Silicone is a highly recyclable material, and manufacturers are working to establish recycling programs to ensure that used pads can be processed and reused in the production of new electronic components.

Thermal conductive silicone pads play a vital role in thermal management of electronic devices, and their structural and environmental protection are key considerations in their design and manufacturing. The combination of a silicone matrix and thermally conductive filler allows these pads to efficiently transfer heat while also providing electrical insulation. In addition, the use of environmentally friendly materials and manufacturing processes emphasizes the commitment to sustainability in the production of thermal silicone pads. As electronic systems continue to advance, the development of thermally conductive silicone pads that prioritize performance and environmental responsibility is critical to a sustainable and efficient future.

Post time: Jul-23-2024