Carbon fiber technology has attracted attention from various industries due to its excellent performance. In recent years, it has entered the field of thermal management with its superior performance, replacing traditional materials such as silicone. In this article, we’ll explore the advantages of carbon fiber thermal pads over silicone thermal pads.

1. Higher thermal conductivity:

The thermal conductivity of carbon fiber thermal pads is significantly higher than that of silicone thermal pads. This property allows them to efficiently transfer heat generated by electronic components to the surrounding environment. Carbon fiber pads have higher thermal conductivity and can effectively dissipate and dissipate heat, thereby reducing the temperature and improving the performance of the electronic devices in which they are used.

2. Lower thermal resistance:

When it comes to thermal management, thermal resistance is a key factor. Carbon fiber thermal pads have lower thermal resistance compared to silicone pads. This means heat can flow through the carbon fiber pad more easily and quickly, minimizing hot spots and maintaining optimal operating temperatures for electronic components. Lower thermal resistance improves device stability, longevity and reliability.

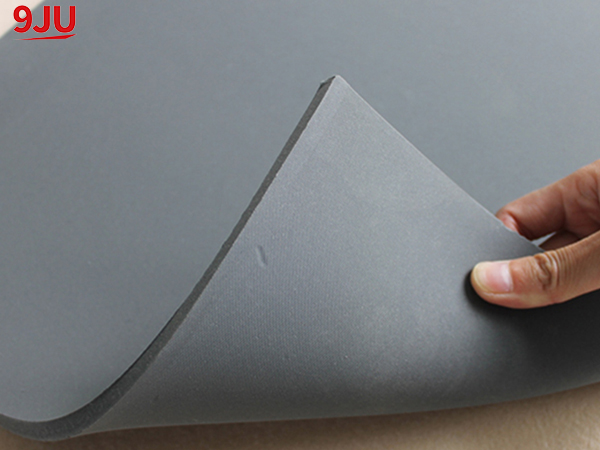

3. Excellent compressibility:

Carbon fiber thermal pads have excellent compression properties, allowing them to conform to irregular surfaces and effectively fill gaps. This property ensures that there are no air pockets or uneven contact points between the electronic components and the heat sink, maximizing heat transfer efficiency. The compressibility of carbon fiber pads also makes installation and removal easier, simplifying maintenance procedures.

4. Electrical isolation:

Unlike silicone pads, carbon fiber thermal pads have electrical isolation properties. This is particularly advantageous in applications where electrical insulation is required, preventing any short circuits or leakage currents. The carbon fiber pad acts as a protective barrier between the heat sink and electronic components, reducing the risk of damage from conductivity.

5. Durability and lifespan:

Carbon fiber is known for its strength and durability. Thermal pads made of carbon fiber materials have strong wear resistance, tear resistance and fatigue resistance. Unlike silicone mats, which can degrade or become damaged over time, carbon fiber mats maintain their performance and structural integrity over time. The extended service life ensures that thermal management solutions using carbon fiber pads provide long-term benefits, reducing the need for frequent replacement.

6. Thin and light:

Carbon fiber materials are inherently light and thin, making them ideal for thermal management in space- or weight-constrained applications. Silicone pads, on the other hand, tend to be thicker and heavier. The lightweight nature of carbon fiber thermal pads allows for easy handling during assembly, minimizes structural stress on electronic components, and allows for more compact designs.

7. Environmental considerations:

Carbon fiber thermal pads are more environmentally friendly than silicone pads. They are often manufactured using sustainable processes and do not release harmful substances or emissions during their service life. Additionally, carbon fiber is recyclable, helping to reduce waste and environmental impact.

In conclusion, carbon fiber thermal pads have many advantages over silicone thermal pads. Carbon fiber pads are becoming an excellent choice for thermal management in a variety of electronic applications due to their high thermal conductivity, low thermal resistance, excellent compressibility, electrical isolation, durability, lightweight and environmental considerations. Not only do they improve equipment performance and reliability, they also help create a more sustainable and efficient future.

Post time: Nov-27-2023