JOJUN EXCELLENT MANUFACTURER OF THERMAL FUNCTIONAL MATERIAL

Focus on heat dissipation, heat insulation, thermal insulation material production for 15 years

- tiger.lei@jojun.net

- 24-hour VIP service hotline:+86 13656269868

JOJUN-8900 Series Thermal Paste

★ Typical Properties of JOJUN-8900 Series Thermal Paste

|

Thermal Conductive Paste |

|||

|

Property |

Unit |

Product Series |

Test Method |

|

JOJUN-8350 |

|||

|

Color |

|

Gray |

Visual |

|

Density |

g/cc |

3.1 |

ASTM D792 |

|

Extrusion Speed @30cc, 90psi |

g/min |

10-90 |

|

|

Application Temperature |

℃ |

-50~+200 |

|

|

Flammability Class |

|

V0 |

UL94 |

|

Thermal Conductivity |

W/m-K |

3.5 |

ASTM D5470 |

|

Breakdown Voltage |

KV/mm |

>5 |

ASTM D149 |

|

Volume Resistivity |

ohm-cm |

10^13 |

ASTM D257 |

|

Dielectric Constant |

1MHz |

7 |

ASTM D150 |

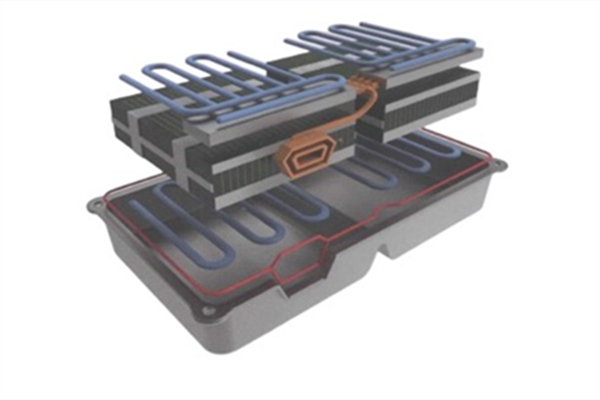

★ Application

LED chip

Communication equipment,

Mobile phone CPU,

Memory module,

IGBT

Power modules,

Power semiconductor field.

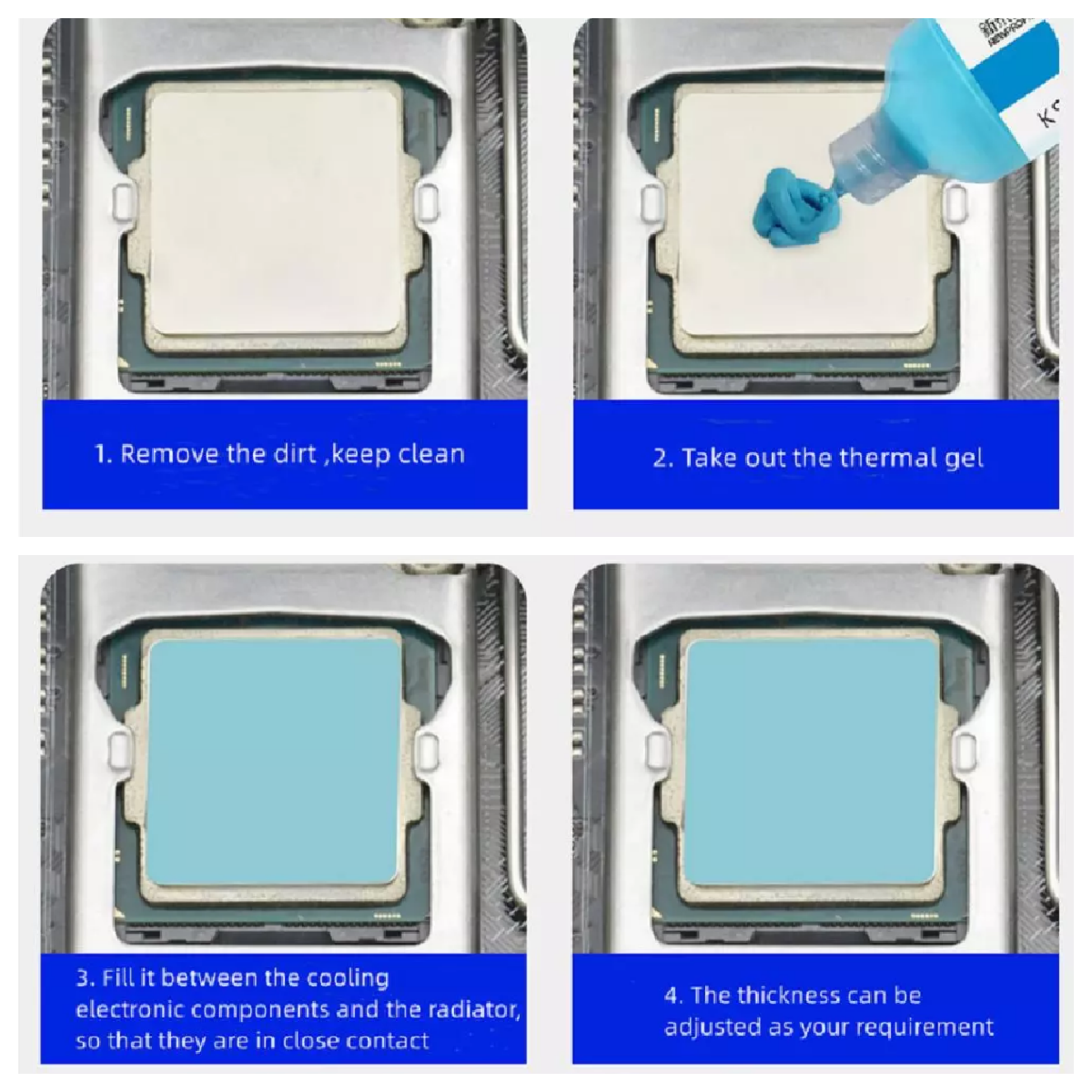

★ Usage

★ Production Process

Mix Stir

Extrusion

Thermal Pad Production Line

Crop

Package

Outgoing Goods

★R&D Center

Voltage Breakdown Tester

Thermal Conductivity Tester

Kneader

Laboratory

★Features And Benefits

Good heat conductivity : 9 W/M-K

Two-component material, easy to store;

Excellent high and low temperature mechanical properties and chemical stability;

The curing time can be adjusted according to temperature.

Automatic equipment can be used to adjust the thickness;

Easily used for automatic operation of dispensing system.

★ Certificates

Features of Thermal Products

-

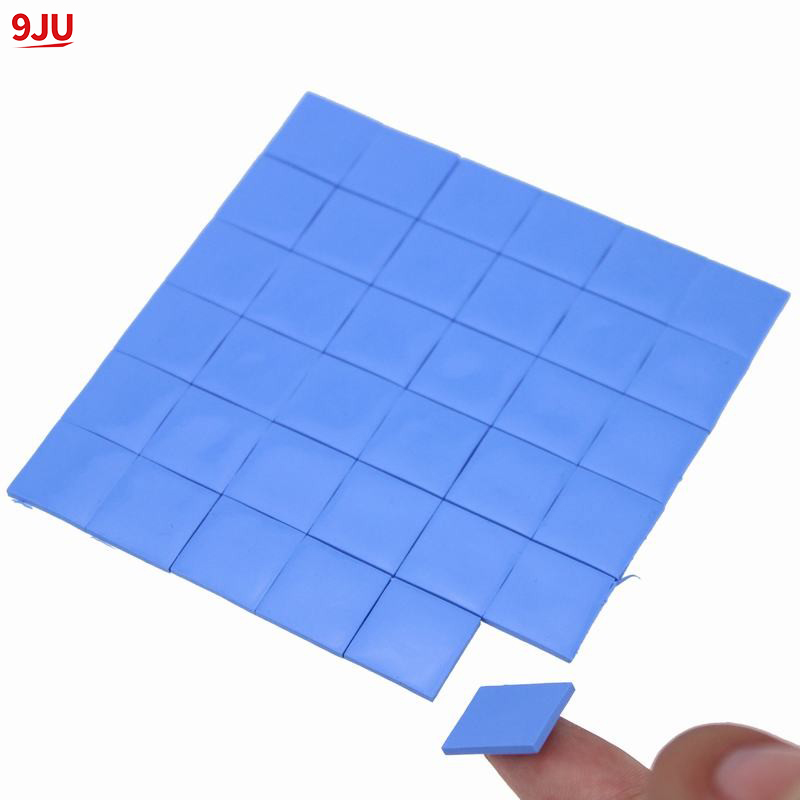

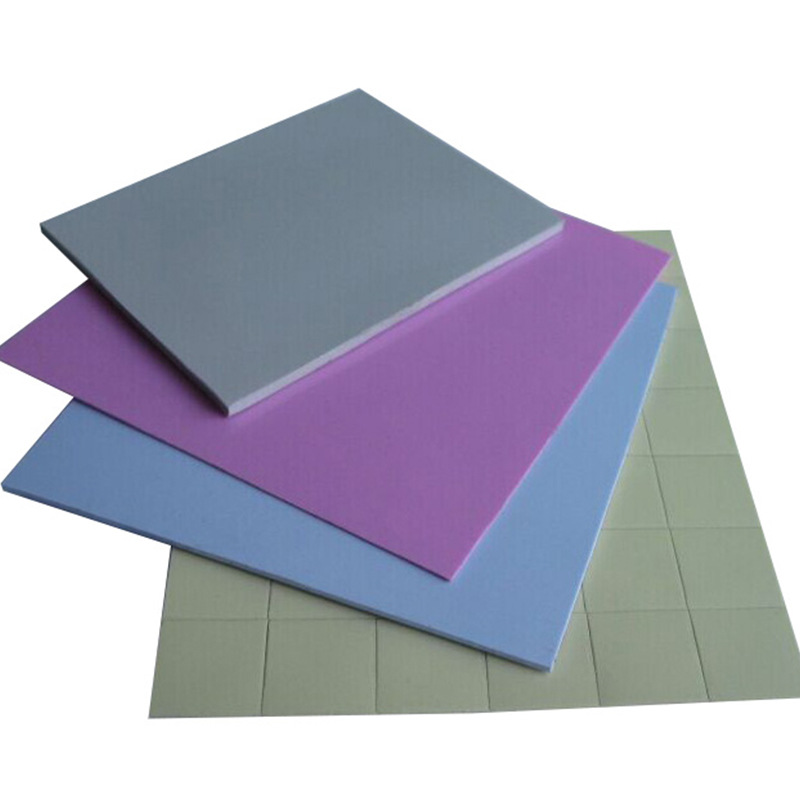

Features of Thermal Pad

1. Good thermal conductivity: 1-15 W/m-K.

2. Low hardness: The hardness ranges from Shoer00 10~80.

3. Electrically insulating.

4. Easy to assembly. -

Features of Thermal Paste

1. Two-part dispensable gap filler, liquid adhesive.

2. Thermal conductivity: 1.2 ~ 4.0 W/m.K.

3. High voltage insulation, high compression, good temperature resistance.

4. Compression application, can achieve automated operations. -

Features of Thermal Grease

1. Low oil separation (towards 0).

2. Long-lasting type, good reliability.

3. Strong weather resistance (high and low temperature resistance -40~150 ℃).

4. Moisture resistance, ozone resistance, aging resistance.