JOJUN EXCELLENT MANUFACTURER OF THERMAL FUNCTIONAL MATERIAL

Focus on heat dissipation, heat insulation, thermal insulation material production for 15 years

- tiger.lei@jojun.net

- 24-hour VIP service hotline:+86 13656269868

JOJUN-8600 Series Thermal Paste

★ Typical Properties of JOJUN-8600 Series Thermal Paste

|

Thermal Conductive Paste |

|||

|

Property |

Unit |

Product Series |

Test Method |

|

JOJUN-8600 |

|||

|

Color |

|

Blue |

Visual |

|

Density |

g/cc |

3.2 |

ASTM D792 |

|

Extrusion Speed @30cc, 90psi |

g/min |

10-90 |

|

|

Application Temperature |

℃ |

-50~+200 |

|

|

Flammability Class |

|

V0 |

UL94 |

|

Thermal Conductivity |

W/m-K |

6 |

ASTM D5470 |

|

Breakdown Voltage |

KV/mm |

>5 |

ASTM D149 |

|

Volume Resistivity |

ohm-cm |

10^13 |

ASTM D257 |

|

Dielectric Constant |

1MHz |

7 |

ASTM D150 |

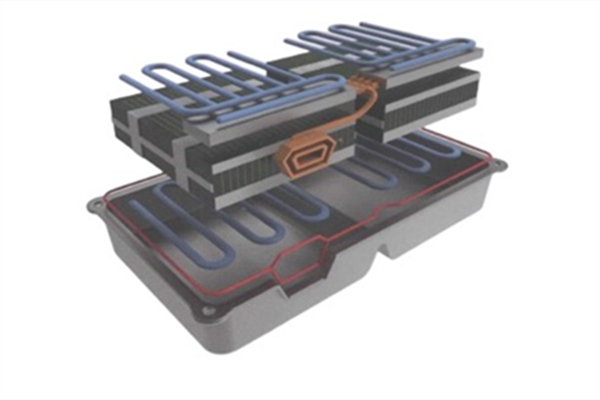

★ Application

LED chip

Communication equipment,

Mobile phone CPU,

Memory module,

IGBT

Power modules,

Power semiconductor field.

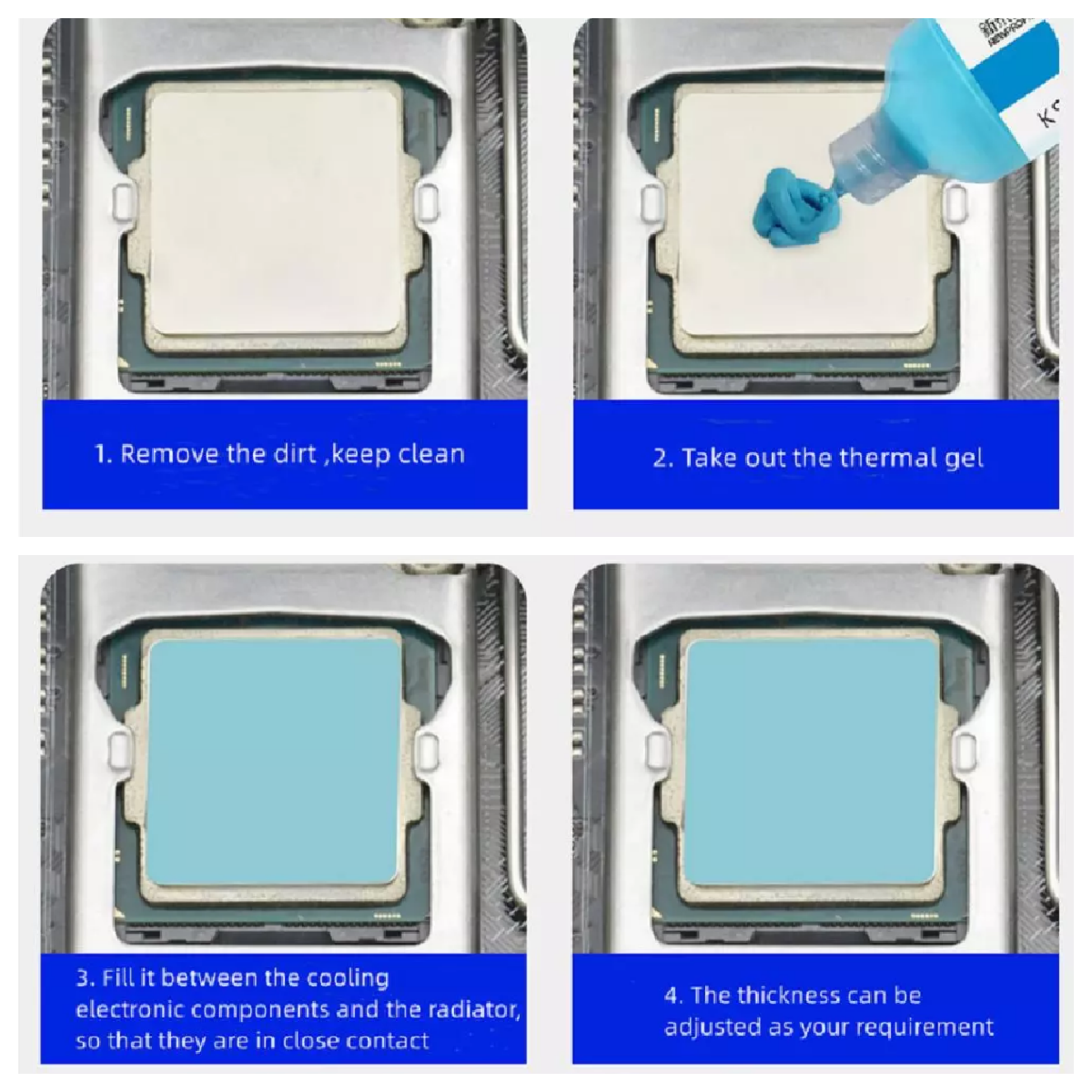

★ Usage

★ Production Process

Mix Stir

Extrusion

Thermal Pad Production Line

Crop

Package

Outgoing Goods

★R&D Center

Voltage Breakdown Tester

Thermal Conductivity Tester

Kneader

Laboratory

★Features And Benefits

Compared with thermal pad, thermal paste is softer and has better surface affinity. It can be compressed to a very low thickness, which significantly improves the heat transfer efficiency, and can be compressed to 0.1mm at the lowest. At this time, the thermal resistance can range from 0.08℃·in2/W to 0.3 ℃·in2/W, which can reach the performance of part of the silicone grease. In addition, thermal paste has almost no hardness, after the use of the equipment will not produce internal stress.

Thermal paste is easier to work with than thermal grease. The general use of silicone grease is screen or steel plate printing, or direct brush coating, is very unfriendly to the user and the environment, and because of its certain fluidity, generally can not be used for thicker than 0.2mm occasions.

And the thermal conductivity mud arbitrary molding into the desired shape, for the uneven PCB board and irregular devices (such as batteries, components corner parts, etc.), can ensure good contact. Thermal gel has a certain adhesion, and will not have the problem of oil and dry, has a certain advantage in reliability.

★ Certificates

Features of Thermal Products

-

Features of Thermal Pad

1. Good thermal conductivity: 1-15 W/m-K.

2. Low hardness: The hardness ranges from Shoer00 10~80.

3. Electrically insulating.

4. Easy to assembly. -

Features of Thermal Paste

1. Two-part dispensable gap filler, liquid adhesive.

2. Thermal conductivity: 1.2 ~ 4.0 W/m.K.

3. High voltage insulation, high compression, good temperature resistance.

4. Compression application, can achieve automated operations. -

Features of Thermal Grease

1. Low oil separation (towards 0).

2. Long-lasting type, good reliability.

3. Strong weather resistance (high and low temperature resistance -40~150 ℃).

4. Moisture resistance, ozone resistance, aging resistance.