JOJUN EXCELLENT MANUFACTURER OF THERMAL FUNCTIONAL MATERIAL

Focus on heat dissipation, heat insulation, thermal insulation material production for 15 years

- tiger.lei@jojun.net

- 24-hour VIP service hotline:+86 13656269868

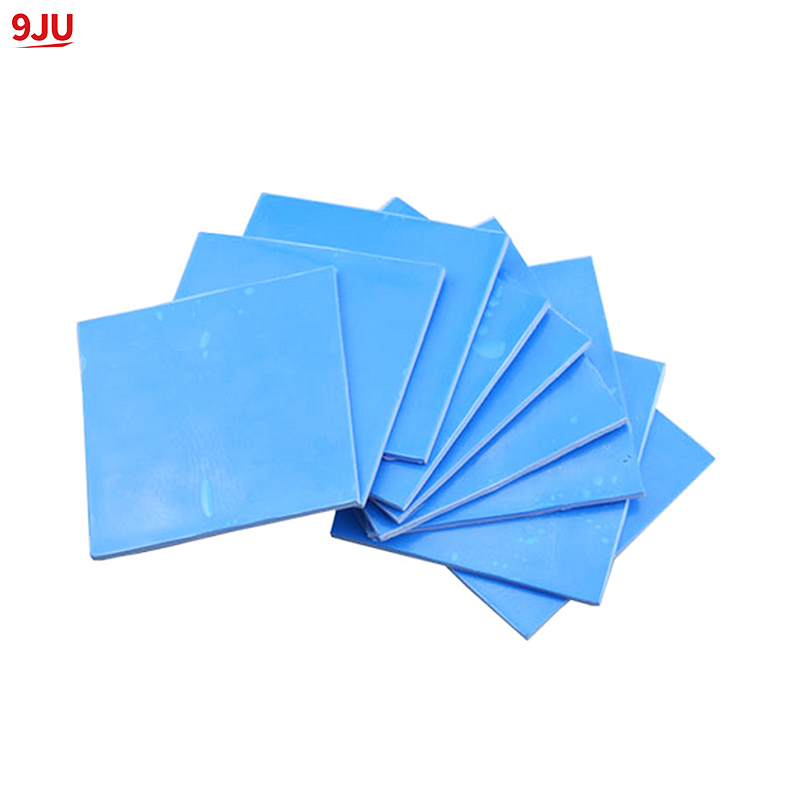

JOJUN-6100 Series Thermal Pad

★ Typical Properties of JOJUN-6100 Series Thermal Pad

|

Typical Properties Of JOJUN6100 |

|||

|

Property |

Unit |

Product Series |

Test Method |

|

JOJUN6100 |

|||

|

Color |

|

Customized |

Visual |

|

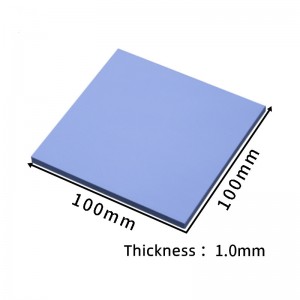

Thickness |

mm |

0.5-5 |

ASTM D374 |

|

Specific Gravity |

g/cc |

2.8 |

ASTM D792 |

|

Hardness |

Shore oo |

30-70 |

ASTM D2240 |

|

Application Temperature |

℃ |

-50 - +200 |

|

|

Flammability Class |

|

V0 |

UL94 |

|

Thermal Conductivity |

W/m-K |

1 |

ASTM D5470 |

|

Breakdown Voltage |

KV/mm |

>6 |

ASTM D149 |

|

Volume Resistivity |

ohm-cm |

10 ^14 |

ASTM D257 |

|

Dielectric Constant |

1MHz |

7 |

ASTM D150 |

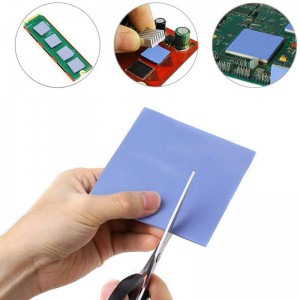

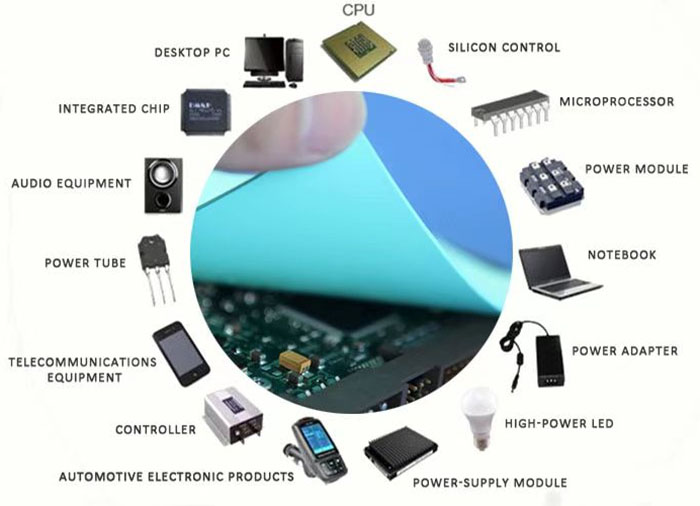

★ Application

1. LED industry

The thermal conductive gasket is used between the aluminum substrate and the heat sink.

The thermal conductive gasket is used between the aluminum substrate and the shell.

2. Power industry

Use the heat conduction between MOS tube, transformer (or capacitor/PFC inductor) and heat sink or housing.

3. Communication industry

Thermal conduction and heat dissipation between the main board IC and the heat sink or shell.

Heat conduction and heat dissipation between the set-top box DC-DC IC and the shell.

4. Automotive Electronics Industry

Thermal conductive gaskets can be used in automotive electronic industry applications (such as xenon lamp ballasts, stereos, vehicle series products, etc.).

5. PDP/LED TV

Heat conduction between power amplifier IC, image decoder IC and heat sink (housing).

★ Production Process

Mix Stir

Extrusion

Thermal Pad Production Line

Crop

Package

Outgoing Goods

★R&D Center

Voltage Breakdown Tester

Thermal Conductivity Tester

Kneader

Laboratory

★ Popular Science Knowledge

Thermal conductive gaskets are used to fill the air gap between the heating device and the heat sink or metal base. Their flexible and elastic characteristics enable them to cover very uneven surfaces. Heat is transmitted from the separation device or the entire PCB to the metal shell or diffusion plate, which can improve the efficiency and service life of the heating electronic components. The heat conduction pad is installed between the heat dissipation cold plate and the heating chip to transmit the heat generated by the chip to the heat dissipation cold plate, thereby reducing the temperature of the chip. The compression stress will occur when the heat conduction pad is compressed. The compression stress will increase with the increase of the compression amount. When selecting the heat conduction pad, pay attention that the compression stress of the heat conduction pad during compression should not be greater than the maximum required pressure of the heating chip, otherwise the chip will be damaged.

★ Why Choose Us?

1. Professional R&D team

Application test support ensures that you no longer worry about multiple test instruments.

2. Product marketing cooperation

The products are sold to many countries all over the world.

3. Strict quality control

4. Stable delivery time and reasonable order delivery time control.

We are a professional team, our members have many years of experience in international trade. We are a young team, full of inspiration and innovation. We are a dedicated team. We use qualified products to satisfy customers and win their trust. We are a team with dreams. Our common dream is to provide customers with the most reliable products and improve together. Trust us, win-win.

★ Certificates

Features of Thermal Products

-

Features of Thermal Pad

1. Good thermal conductivity: 1-15 W/m-K.

2. Low hardness: The hardness ranges from Shoer00 10~80.

3. Electrically insulating.

4. Easy to assembly. -

Features of Thermal Paste

1. Two-part dispensable gap filler, liquid adhesive.

2. Thermal conductivity: 1.2 ~ 4.0 W/m.K.

3. High voltage insulation, high compression, good temperature resistance.

4. Compression application, can achieve automated operations. -

Features of Thermal Grease

1. Low oil separation (towards 0).

2. Long-lasting type, good reliability.

3. Strong weather resistance (high and low temperature resistance -40~150 ℃).

4. Moisture resistance, ozone resistance, aging resistance.